- Gennaio 27, 2022

- Posted by: Oliver

- Categoria: Economics, Finance & accounting

The global, digital economy is radically reinventing business. For leaders across industries, it’s not just the pace of business that’s changed – it’s everything from customer expectations to competitive landscapes.

87 percent of CSCOs say it is extremely difficult to predict and manage disruptions

According to IDC, 33 percent of all manufacturing and retail companies will be disrupted by digitally-enabled competitors within the next three years.

Today more than ever, businesses must evolve to stay competitive. Savvy leaders are looking to their supply chains to do the heavy lifting, driving differentiation that impacts quality, delivery, costs, customer satisfaction and more.

Foundations for Building a Smarter Supply Chain

A smarter supply chain, powered by AI and blockchain, provides greater visibility and insights into the end-to-end supply chain – including the transactional lifecycle and partner ecosystem. It leverages the power of AI to connect and correlate data from disperse and disparate systems and sources, and sorts through data overload to provide new insights and relevant alerts. It complements and elevates existing systems and investments.

AI can also help you proactively predict, assess and mitigate disruptions and risks. A smarter supply chain that leverages this technology builds significantly more resiliency and responsiveness.

Leading companies are learning firsthand how these disruptive technologies enable improved efficiency and reduced costs. They represent a new era of supply chain management, complementing and elevating existing solutions across planning, sourcing, inventory, fulfillment, logistics and supply assurance.

When you combine AI and blockchain, the impact is exponential. Supply chain solutions can embed these technologies in meaningful ways, such as to drive improved insights and usability of the vast data affecting supply chain organizations. From correlation and anomaly detection in business transactions, to gaining insights by tapping into internal and external data sources, with these technologies organizations can proactively get ahead of events. When AI and blockchain are combined they can enable a powerful platform that provides both a source of shared, immutable data for suppliers and partners – with the capability to immediately identify trading partner behaviors and events.

The companies referenced [below] in these case studies are all early leaders in implementing AI and blockchain. All of them sought to be the disruptor in their industry, rather than be disrupted. They each were able to build, with the help of IBM, capabilities leveraging their existing systems and applications to drive immediate value in specific use cases prioritized by the business.

Illuminate the 80% of data that is dark and unstructuredGain End-to-End Visibility

- Quickly correlate and understand data from across disparate systems

- Sort through data overload and gain new insights

- Establish shared visibility with partners and key suppliers

Mitigate Disruptions and Risks

- Proactively predict, assess and mitigate disruptions and risks

- Reduce disruption mitigation time and related costs

- Retain knowledge and best practices for future reference

- Help cut disruptions in half with AI-enabled smart- alerts and predictive capabilities

The IBM Supply Chain

IBM, one of the world’s best-known technology companies, runs a complex global supply chain with strategic manufacturing facilities located around the world and workers spread across more than 40 countries to support customers in more than 170 countries.

To meet the high configuration product demand, the IBM Supply Chain (IBM SC) operates in a hybrid model of build-to-plan and build-to-order.

IBM also collaborates with many hundreds of suppliers across its global, multi-tier supplier network.

Over the past decade, IBM has exhibited a relentless commitment to building smarter supply chains to quickly and effectively navigate global disruptions.

The focus has been on building a cognitive supply chain that embraces an agile culture of innovation, invests in team members’ growth and engagement, focuses on clients’ needs and successes, and leverages exponential technologies to deliver greater value.

Emphasis on the term agile culture of innovation. In today’s increasingly competitive and turbulent business environment, agility has been widely recognized as one of the fundamental characteristics of forward-looking supply chains that could render positive impacts on the financial, market, and operational performance.

Recently, as companies try to deal with the unprecedented and volatile changes in both demand and supply due to the COVID-19 pandemic, focused attention toward supply chain agility (SCA) is accelerating.

However, there remains a great deal of confusion around the concept of agility. In discussing SCA with various companies, we often ask them to self-evaluate their current level of agility. A typical response is: “We’re very agile. When a situation comes up for unanticipated customer demand or supply disruption, we do whatever it takes to satisfy the customer.”

Frequently accompanying such a response are heroic stories of how significant the additional efforts and resources are expended to meet those needs. It is apparent from these conversations that what is thought of as agility is in reality heady reactive problem solving, and there remains confusion between successful fire-fighting capability and what true agility really means.

Admittedly, any endeavor to bring SCA into fruition would seem to be impossible without the fundamental clarity of what agility construes and what its applications might look like. This article intends to bring clarity to the concept of SCA and provide best-practice examples exercised at IBM to further bring the conceptual perspective into the real-world mentality.

Bringing Clarity to the Concept of Supply Chain Agility

In its broadest sense, SCA is consistently viewed as the ability of a supply chain to effectively and timely respond to changes. However, a look into a more granular question of what exactly constitutes SCA highlights the requirements to successfully develop this dynamic capability and reveals several concepts used in relation to SCA, notably flexibility, adaptability, and responsiveness.

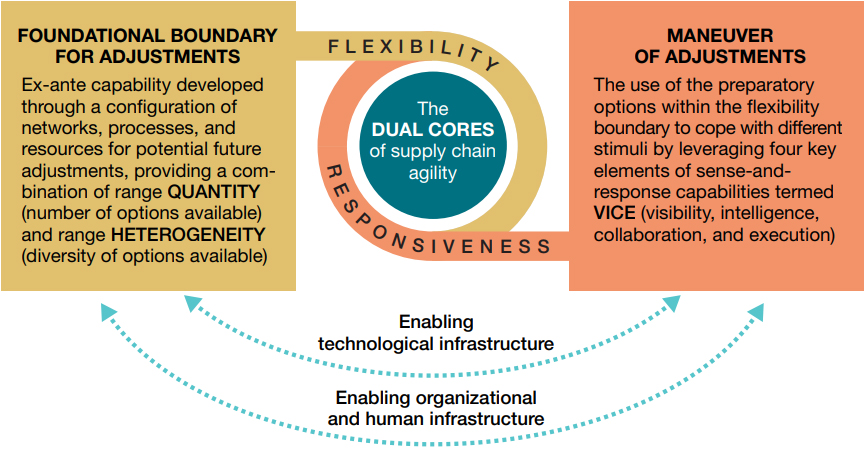

Confusion inevitably abounds as these popular connotations are often used interchangeably, referred to without clear distinction, or portrayed with inconsistent depictions. Propitiously, emerging conceptual consensuses in research on SCA can be discerned and provide a basis for the conceptual framework shown in Figure 1.

Figure 1: Supply Chain Agility Framework

Source: Center for Supply Chain Research, Penn State University

In a nutshell, SCA is the ability of a firm and its supply chain members to effectively and timely respond to short-term, temporary changes in both the supply chain and market environment by adjusting resources, tactics, and operations within the existing supply chain structure.

Here, supply chain agility is distinguished from supply chain adaptability that focuses on addressing long-term, fundamental changes (e.g., demographic change, radical technological advances) to the extent that involves the reconfiguration of the supply chains. As such, agility is a key element of adaptability and, by extension, a related concept of resilience that required the supply chain’s ability to adapt in response to disruptions.

The Dual Cores: Flexibility and Responsiveness

SCA is squarely founded on dual cores that must be incongruous coexistence, namely flexibility and responsiveness. Essentially, flexibility is a foundational boundary of a supply chain’s ability to adjust that will be constrained, and responsiveness primarily concerns a nimble maneuver of adjustments within the flexibility boundary to address different stimuli (e.g., demand changes, supply shortages, natural disaster events, and so on).

More specifically, flexibility centers on pre-establishing a broad range of alternative options for potential future adjustments in supply chains. It involves configurations of different supply chain elements that encompass a breadth of processes (e.g., sourcing, manufacturing, and logistics), and the depths of flexibility attributes and hierarchical layers.

Flexibility attributes could vary in terms of volume, variety, functionality, and skill; while the hierarchical layers could involve strategic/operational/ tactical management layers, and intra-firm and interfirm network layers. Altogether, the range of alternatives, which prescribes the flexibility boundary, can be afforded through a combination of range quantity (the number of options available) and range heterogeneity (the diversity of options available in terms of functions, attributes, and layers).

In turn, supply chain responsiveness entails the use of the preparatory options to cope with different stimuli by leveraging sense-and-response capabilities. Sensing capability is generally associated with aptitudes such as alertness, awareness, visibility, and decisiveness; whereas qualities such as speed, alignment and collaboration are often identified with responding capability.

Overall, the sense-and-response capabilities required to achieve SCA can be categorized into four salient elements, hereafter referred to as VICE: visibility, intelligence, collaboration, and execution.

Enabling Infrastructure: Technology, Organization and Human

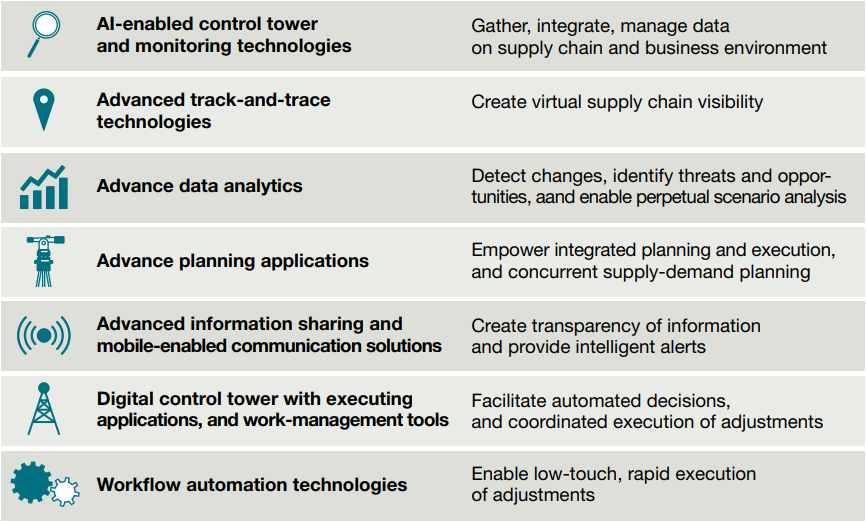

Technologies are an essential component that empowers the dual cores of SCA. Advances in industrial technologies now allow a higher degree of freedom and intelligence for supply chains to process a range of different products, batch/order sizes, and volumes without significant penalties in either time or effort. Likewise, responsiveness is enabled through a portfolio of digital and IT applications that empower a supply chain’s ability to tap into its pre-established flexibilities as illustrated in Figure 2.

Figure 2: Supply Chain Responsiveness Technology Enablers

Source: Center for Supply Chain Research, Penn State University

Moreover, traditional organization models that have evolved primarily based on the assumptions of stability and predictability are replaced by agile organization models built on the agile thinking philosophy. An agile organizational infrastructure resembles a network of smaller empowered units, with fewer hierarchical layers, greater transparency, and less authoritative governance than the traditional counterparts. Meanwhile, human enablers are fortified with a growth mindset that is key for each person to be agile in their attitude and in their approach to new technologies.

Putting Conceptual Clarity to Work at IBM

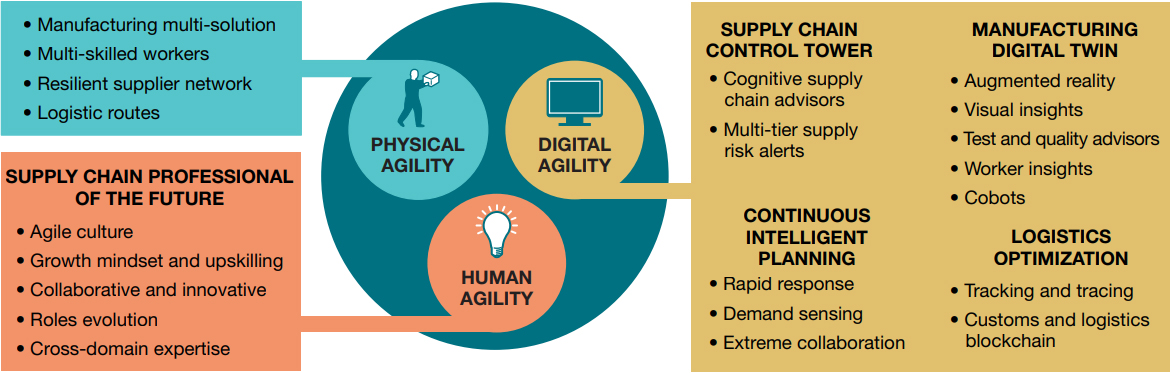

IBM SC’s transformation, depicted in Figure 3, focused on building a cognitive supply chain that embraces an agile culture of innovation, invests in team members’ growth and engagement, focuses on clients’ needs and successes, and leverages exponential technologies to deliver greater value.

Figure 3: Game Plan for Driving Agility in IBM Supply Chain

Source: IBM Supply Chain, IBM Corporation

Manifestations of the SCA dual cores at IBM SC span across sourcing, manufacturing, and logistics processes, as well as intra- and inter-firm network layers. Here, multisourcing and alternative or substitute parts promote sourcing flexibility; while responsiveness is realized through readily available parts information and collaboration with suppliers across the network down to tier-2 and tier-3 levels.

The knowledge of the network of component fabs and assembly facilities can be harnessed through contract manufacturing into IBM manufacturing locations. Close alliance with these contract manufacturers on their manufacturing and supplier networks with visibility of supply, demand, inventory, and issues enables IBM SC with quick insights on developing supply situations. Such insights allow IBM SC to take action prior to negative business impacts arising.

Moreover, within manufacturing, IBM’s multi-skilled workers are cross-trained to support every type of product build. Coupling the ability for rapid configuration conversion in manufacturing build and testing with the multiskilled workers, IBM SC is equipped to deliver ultimate manufacturing flexibility and responsiveness to handle changing demands during peak periods. Equally, within logistics, IBM SC strengthens its ecosystem by partnering with lead logistics providers that specialize in logistics optimization (such as alternate routes) and share in risks with pre-approvals to enhance logistics flexibility.

Overarchingly, concurrent planning is implemented to handle the dynamics of demand planning. IBM SC utilizes scenario analysis for quick assessments of changes in demand between the sales and operations planning cycles, as well as its impact on supply planning across multiple planning horizons. Such planning concurrency provides alignment that enables faster collaboration and response to meet the business needs.

Enabling Manufacturing Agility with Industry 4.0 Technologies

Within manufacturing, digital twins – along with AI, IoT, analytics, and other digital technologies – are integrated into factory operations (see Figure 3) to enhance IBM SC’s ability to quickly adjust to the changing supply chain landscape. Briefly, digital twins equipped IBM SC with the ability to visually model, simulate and optimize real-world assets, operations and processes to predict behaviors and simulate execution success prior to implementation. Digital twins, used in conjunction with mobile tablets enabled with augmented reality, further provide responsive remote assistance to manufacturing for maintenance and troubleshooting.

Also, co-bots (robots integrated with AI) are combined with visual inspection (an AI-powered computer vision solution) to inspect for physical damage before robotic automation starts the assembly process. And while AI advisors use machine learning technologies on structured and non-structured data to aid manufacturing workers in test by recommending repairs; IBM SC’s quality advisors employ analytics to intelligently control the end-to-end supply chain quality data and predict failure rates with recommended actions to mitigate or improve the impact.

Meanwhile, IoT sensors are used in manufacturing for machine storage with data analytics analyzing for occupancy trends to provide insights on optimal storage arrangements, and facilities and worker safety management.

Enabling Responsiveness and Agility with Digital and Human Infrastructure

As illustrated in Figure 4, the integration of people, processes, and technology is key for IBM SC to enable new ways of working ingrained with VICE responsiveness capabilities.

Figure 4: IBM Agile Ways of Working

Source: IBM Supply Chain, IBM Corporation

Principally, data platforms and AI-driven advisors create end-to-end visibility and intelligence for quick, data-driven decision-making. In turn, intelligent workflows capitalize on the data platform and AI-driven advisors to facilitate collaboration and execution of responding actions to address stimuli at hand. And, at the heart of these intricated digital enablers are the people who have evolved from operators to data-savvy orchestrators with a growth mindset.

Developing an Agile Organization with a Growth Mindset

People are regarded as IBM SC’s most important resource and the foundation for an agile organization. Committed to agile thinking and servant leadership, IBM SC supports multi-disciplinary teams with a culture based on collaboration, innovation, trust and diversity, and inclusion.

Here, its leverage of current talent through upskilling is a key success factor to meet the needs of a digital future characterized by a shift from processes being run by people supported by technologies to being run by technology supported by people. Its supply chain talents transition from being a task-oriented operator dependent on finding answers through manual data mining to an orchestrator equipped with immediate access to end-to-end supply chain data. Rapid, informed decision-making and, in certain applicable cases, automated execution of the results of those decisions can then be achieved. As such, these data-savvy orchestrators will be collaborative and innovative in delivering solutions both tactically and strategically.

Equally, a growth mindset is a key for human agility at IBM SC both in terms of their attitude and in their approach to new technologies. While process automation strives to reduce variability, in reality, how people choose to handle variability in events affecting the supply chain can also improve agility. The growth mindset characterized by the belief in themselves to develop their abilities leads to openness for continual learning and an attitude that views setbacks as opportunities for growth. Results are people’s ability improvements through the learning feedback loop that is created by success and lack of success from certain scenarios. Key characteristics of agile supply chain talents nurtured at IBM SC are summarized in Table 1.

Table 1: Key Characteristics of Agile Supply Chain Talents

Source: IBM Supply Chain, IBM Corporation

As an already innovation-driven enterprise, IBM SC further accentuates the significance of organizational and human enablers due to the fact that developing an agile organization and talent goes hand in hand with nurturing innovations. Its experience has taught that by cultivating an environment that encourages workers to be more creative, innovation can permeate into all aspects of their jobs, empowering them to infuse the innovative insights gained in their decisions with greater speed. In this manner, a self-sustaining loop of enhancing supply chain agility is formed wherein organizational and human enablers create an environment to propagate innovation that increases the ability to be more agile which, in turn, leads to more innovation. Essentially, a semi-autonomous positive feedback loop is formed.

Enabling Visibility and Intelligence

Visibility to end-to-end supply chain data both internal and external is made possible by IBM SC’s strategy of harmonizing and expanding its data platform and utilizing a hybrid cloud which improves availability and flexibility for scalability. The data platform integrates internal data with external data, while those pertaining to the networks of suppliers and logistics providers are gathered by leveraging blockchain for customs and logistics data, and IoT track-and-trace smart sensors for location and shipment health monitoring.

Additionally, using platforms powered by IBM’s Watson and cognitive AI capabilities, the supply chain advisors continually ingest the data-in-motion from the execution applications. Instant data insights can thus be provided to its supply chain professionals for monitoring and assessing global and local supply and demand information, along with the part number and component details.

In turn, through IBM SC’s unique dynamic control tower, the data gathered and AIpowered insights produced are made available in real-time for all supply chain functions and locations, creating a single point of truth across the supply chain. The supply chain control tower also creates automatic alerts for delays in transit or out-of-tolerance health indicators on specific shipments. The enhanced transparency into such information as forecast, order, supply, inventory, logistics, and engineering data not only eliminates the need for information requests but also facilitates collaborative problem solving and decision-making processes among all parties involved.

Enabling Collaboration and Execution

Capitalizing on IBM SC’s data platform and AI-driven advisors, intelligent workflows transform manual, rigid well-defined processes into ones that are automated and fluid in responding to different situations. Intelligent workflows digitize existing relationships within the supply chain by leveraging a host of technologies – namely AI, blockchain, IoT, and automation – to provide a reimagined view to demand sensing and conditioning. Additionally, founded on a continuous intelligent planning framework, IBM SC builds intelligent workflows by integrating demand and supply planning with fulfillment, allowing for quicker responses to changes in supply positions.

Furthermore, with the support of AI-driven workflows, repeatable tasks are delegated to digital workers, transforming supply chain professionals into workflow managers.

And, by combining data-savvy orchestrators with the digital workers aiding in the automation, faster decisions and the time to value are further enabled. Overall, intelligent workflows empower IBM SC to bring the ends of a supply chain together much more quickly via the rapid flow of information and automated execution.

IBM Supply Chain Agility in Action

As a result of its transformation, IBM has experienced significant improvement in all supply chain performance aspects of time, cost, and quality. IBM SC is more efficient at tackling reoccurring supply chain challenges, and issues arising from different stimuli are now better understood and solved in minutes instead of hours or days. Collaboration with and management of its supply base is much more effective, with the increased data retrieval and ability to derive meaningful insights with speed. Reduction in inventory, freight logistics costs, and working capital have been achieved, while still maintaining top industry serviceability levels. Here are some specific examples of IBM SC agility in activities that contribute to successful outcomes.

- During peak demand, typically at quarter-end and year-end, IBM SC leverages its multiple qualified production sites and forecast/plan/ship information from multiple sources to maintain flexibility. Multi-skilled workers cross-trained on all products further enable quick changeover frequently during peak demand, thus ensuring full support to each product to serve customers.

- At the onset of the COVID-19 pandemic, potential disruption risks were recognized early, prompting IBM to conduct buffer planning at multiple levels for parts. In-depth tier-2 and tier-3 teams supported by a cognitive advisor had early indications of where lockdowns would occur globally, enabling them to stay one step ahead of COVID-19 shutdowns and keep supply flowing.

Food for Thought

This article underscores the inescapable realities that SCA is becoming mandatory for enterprises seeking to simultaneously foster resilience against disruptions, promote competitive advantages against competitors and provide superior value to customers. Acknowledging that SCA implementation will differ across supply chains, we look into IBM SC approaches to provide a best-practice example of how a truly agile supply chain might be cultivated that it is both prepared and capable of responding to most variations without the need for heroic measures.

Refocus the Agility Lens

Here are key takeaways to guide firms to refocus agility lenses and develop relentless agility in their supply chains.

Flexibility and responsiveness must congruously coexist.

- SCA is founded on dual-core capabilities of flexibility and responsiveness where flexibility prescribes the boundary of alternatives, and responsiveness leverages sense-and response capabilities to maneuver across the pre-established options seamlessly.

- Responsiveness is not possible without certain levels of flexibility, and flexibility without responsiveness is devoid of deployment apparatus by which a supply chain can devise and execute a specific course of action in a timely and cost-effective manner. Enabling infrastructure is required to effectively cultivate the dual-core capabilities.

- A synthesis of visibility, intelligence, collaboration, and execution (VICE) technologies, an agile-thinking approach to organization models, and agile-inspired supply chain talents furnish important sources of enablement to the capabilities of the dual cores.

- Organizational and human enablers are both catalysts for the confluence of agility and innovation that forms a self-sustaining loop of enhancing supply chain agility through innovative thinking.

Supply chains are changing. Here are 5 things we know now.